Large-Aperture Interferometric Optical Profiler

The interferometric probe configured for the ufact series white light optical profilers is the Newview 9000 probe from ZYGO Corporation (USA). ZYGO is a globally recognized leader in optical surface profiling technology at the sub-nanometer scale. The three-dimensional, non-contact surface profilers it manufactures are among the most advanced surface measurement instruments used internationally in both scientific research and industrial fields. Utilizing the industry-preferred principle of white light interferometry (which offers performance superior to laser interferometry profilers and laser confocal microscopes), these systems perform rapid, highly repeatable, high-resolution measurements of three-dimensional surface topography. They are capable of quantifying key parameters such as critical dimensions, wear area, wear volume, and roughness.

- CrysNova

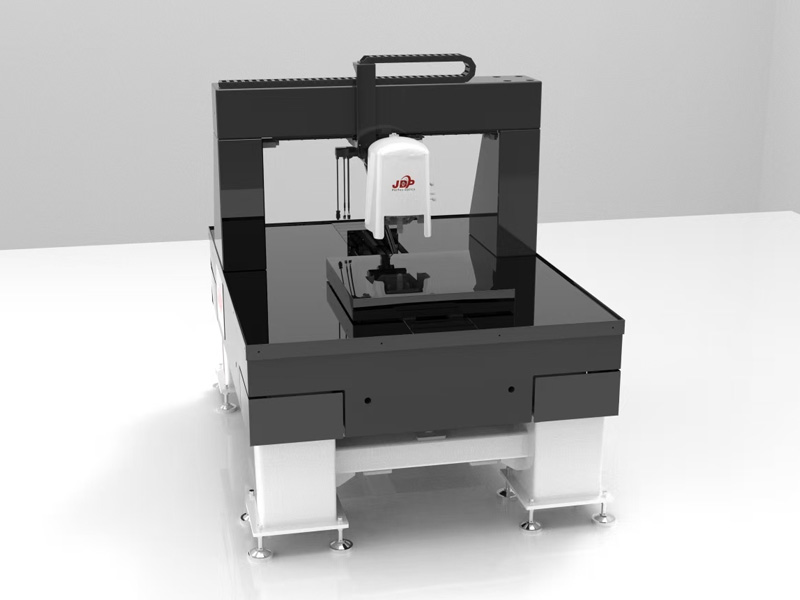

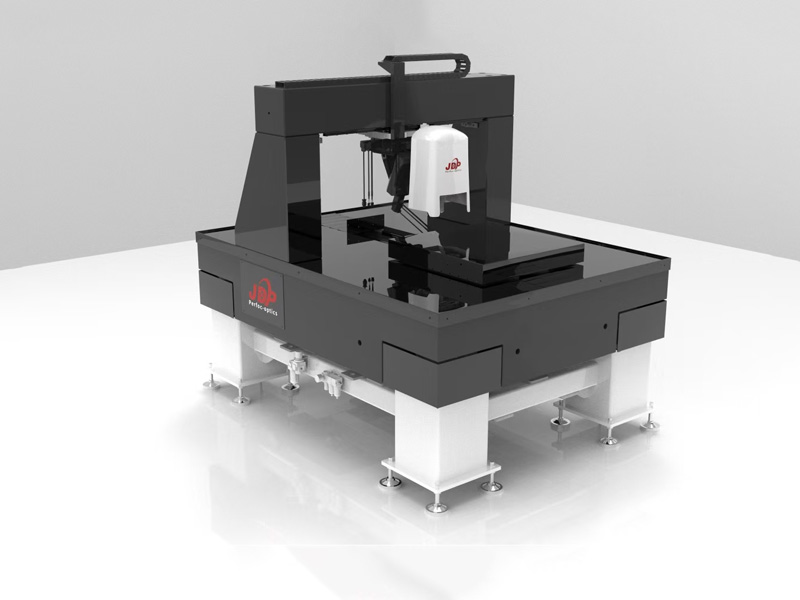

- JDP-ufact 1200

- ≤0.01mm

- ≥500mm×500mm

- Covers a range of ±6°

- Information

Product Overview

The white light optical profiler, known for its nanometer-level measurement accuracy, offers significant advantages such as speed, non-contact operation, non-destructiveness, and consumable-free measurement. Consequently, it is widely used in scientific research for characterizing a variety of surface microstructures. As mechanical precision and optical fabrication capabilities advance, the processing of ultra-smooth and sub-nanometer surfaces is becoming increasingly common. The quantification of these surfaces has become critical for process control.

Initially applied within the optics manufacturing industry, the optical profiler is now utilized in a diverse range of microscopic measurement applications, including but not limited to: metal etching, thin-film thickness and stress characterization, solar cell surface inspection, MEMS characterization, semiconductor devices, microlens topography, and roughness characterization of machined components. Representative application examples are as follows:

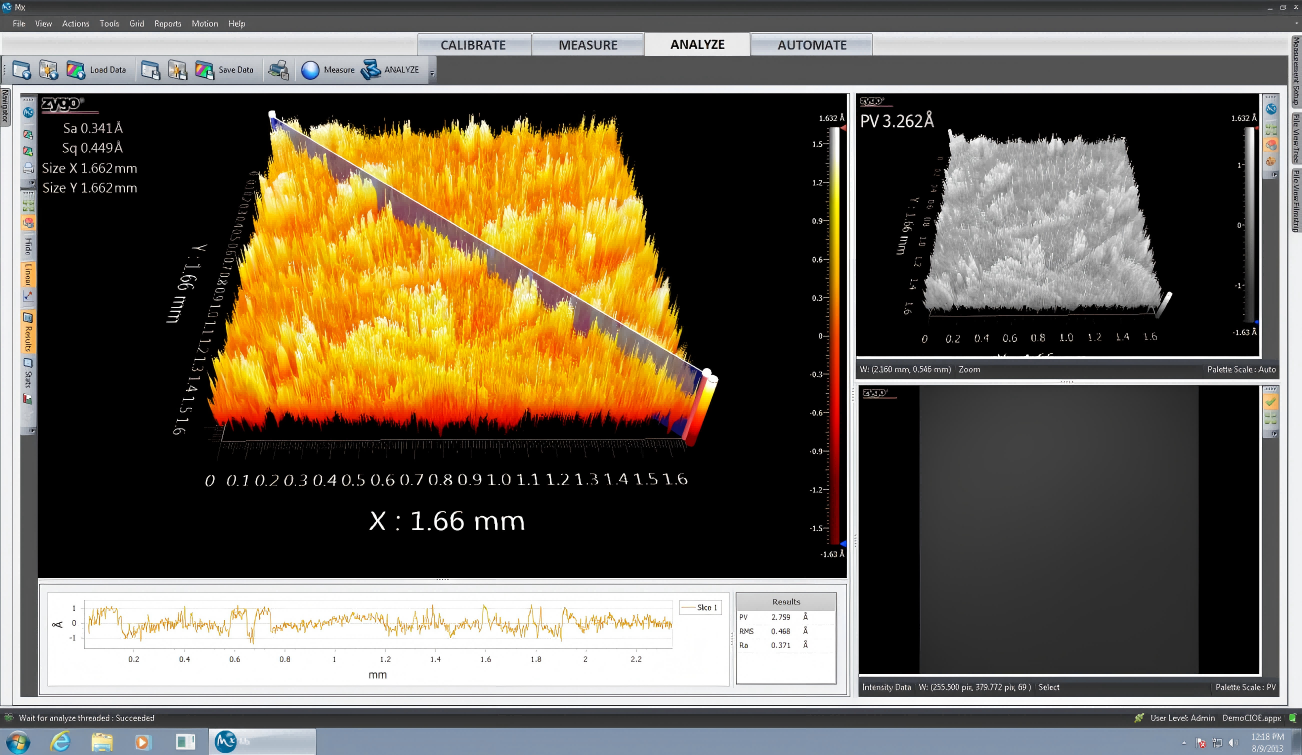

Surface Roughness Measurement

The smallest measurable roughness result directly characterizes the system's noise floor. This noise may originate from optical noise, electronic noise, vibrational environmental influences, and so forth. It signifies that any sample smoother than this, or any signal smaller than this, will be submerged within the system's noise floor. Consequently, this result directly reflects the system's resolution for roughness testing, or in other words, its ultimate capability limit in roughness measurement.

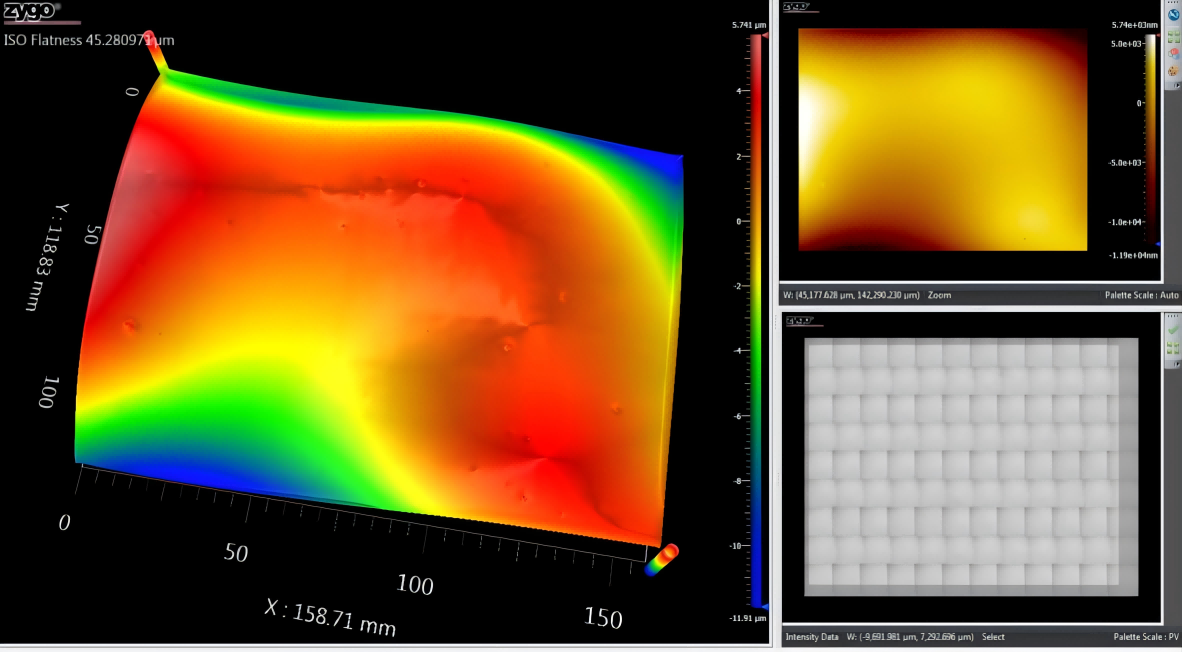

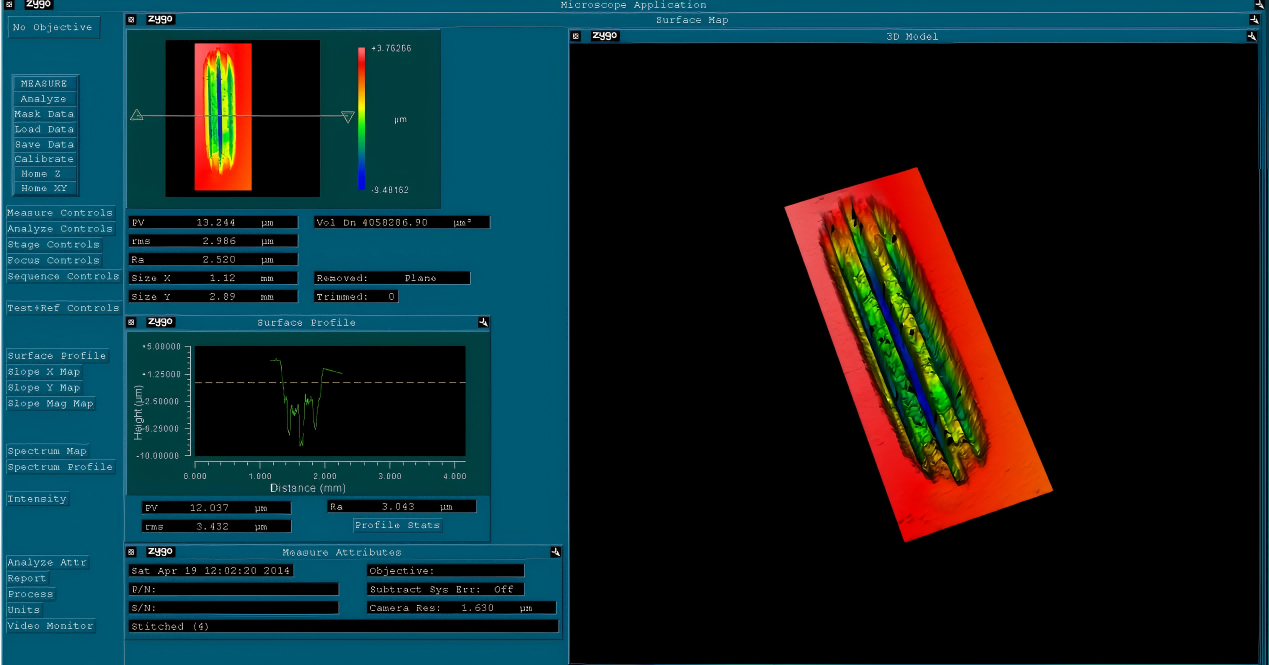

Faster Stitching for Large-Sample Flatness Measurement

A stable and high-performance stitching process makes measuring large samples simple, efficient, and practical.

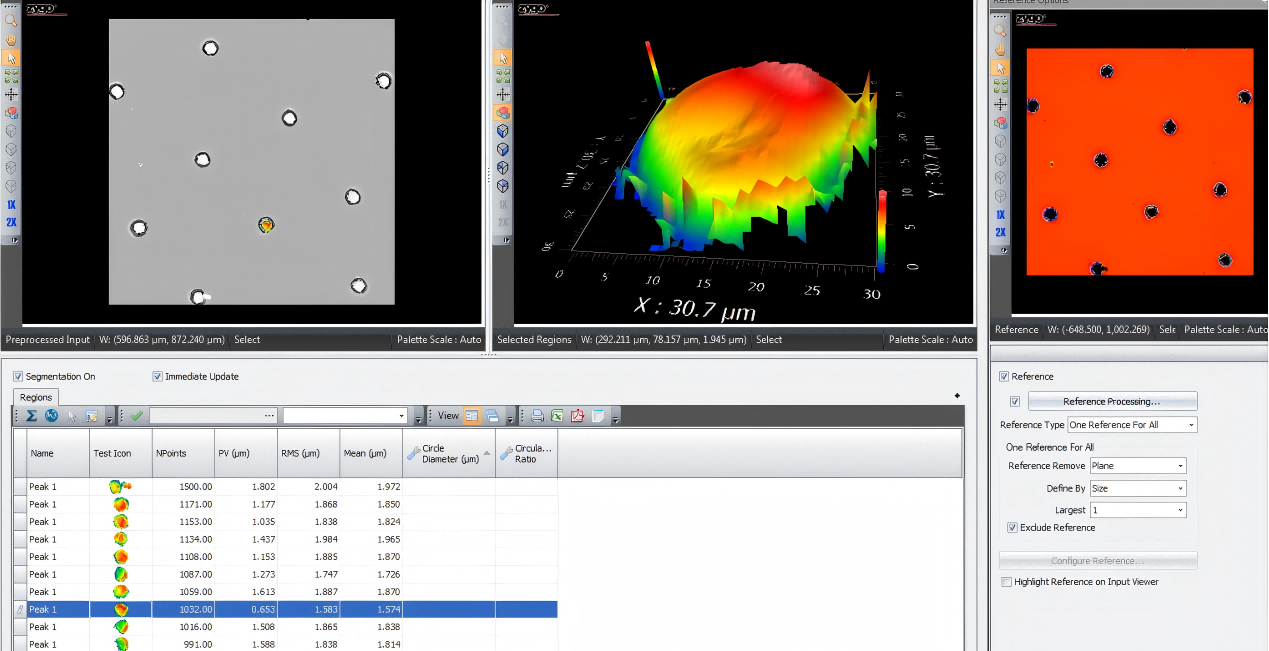

Regional Analysis

It can automatically analyze, isolate, and quantify localized features such as defects and texture. The system provides comprehensive statistics for the entire sample, as well as detailed analysis of individual specific regions, reporting key parameters including area, volume, shape, location, and more.

Micro-Surface Structure Analysis

Specializing in the characterization of surface topography, encompassing three-dimensional form, contour, and texture.